Custom Foam

Custom Foam

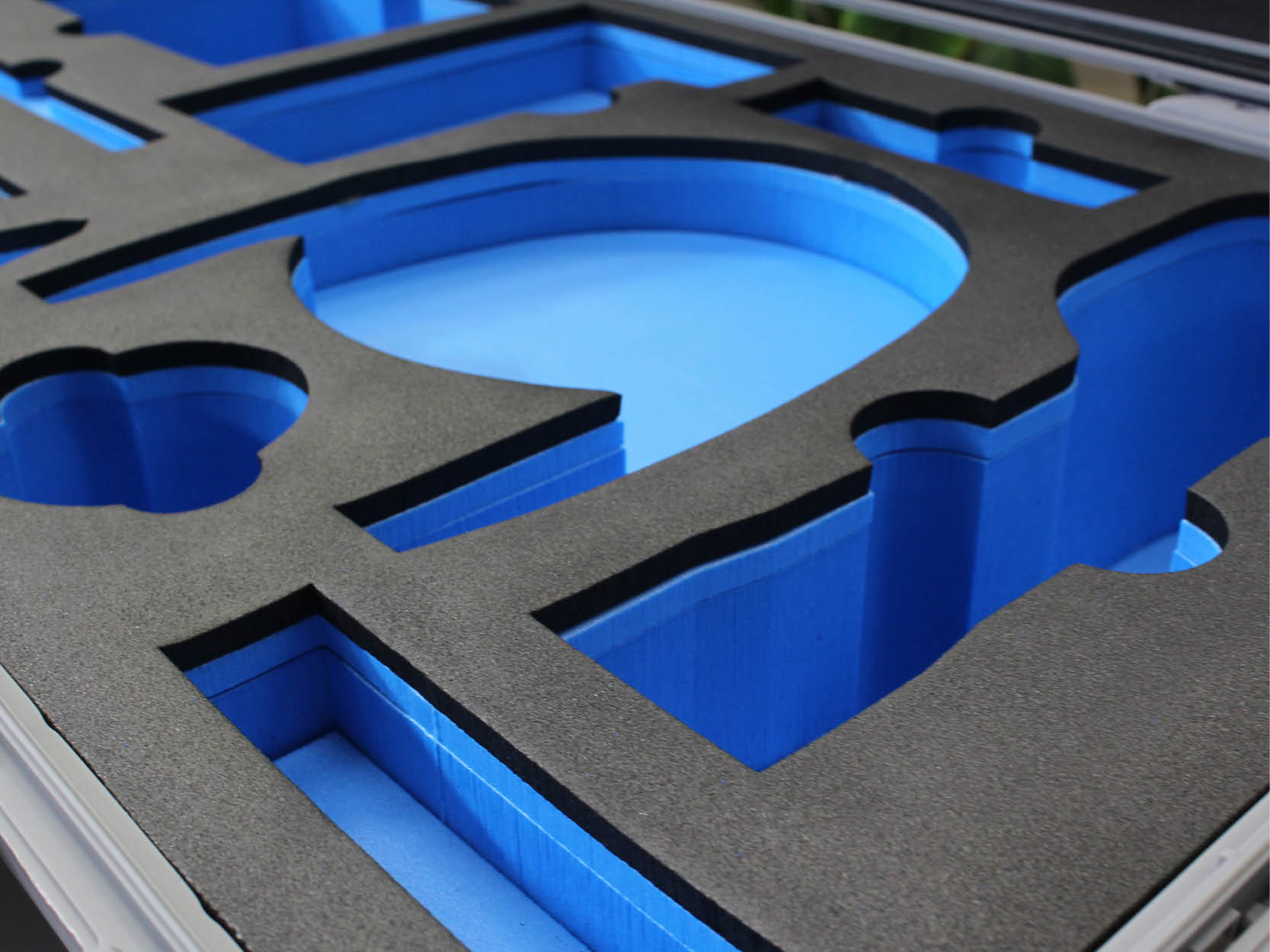

Custom Cushion Engineering

Our Advanced Technical Packaging and Design team uses the latest CAD/CAM software and foam cutting tools to provide precise custom foam inserts for any and all of our cases. If you don’t need the case, we can also provide our custom foam services for any project you might have. Our team strives to provide best-in-industry lead times for all of our custom projects.

Custom foam cushions can be designed and manufactured for any of our cases. We use a variety of varying foam types and densities to protect your equipment depending on the size, weight, and fragility. Some of our typical foam types are listed below:

• Polyethylene

• Polyurethane

• Anti-static

• Various cross link foams

We also use other materials if required to sure up your foam cushion; like ABS plastic for dividers or to sturdy up a foam tray, as well as Velcro or nylon strapping.

We use the most innovative foam cutting tools to provide professional and precise foam cushions. Below is a list of some of our available foam cutting methods:

• CNC

• Water jet

• Die-press

Our engineering team here at OrionCase uses the latest CAD/CAM software to design around your equipment and requirements to provide custom cushions that perform to protect your equipment to the fullest. We can also accept customer supplied CAD drawings in all major formats. Don’t have a drawing? Send us your equipment for us to measure and we’ll take care of it.

Once your custom cushion design complete, we can produce First Article pieces very quickly for test fit and approval.