Specialized Services

Specialized Services

Specialized Services

We offer a number of specialized services, including the fabrication of custom cradles and frames for heavy parts, help with controlling case vibration as well as arranging drop tests, vibration tests and leak tests with independent labs.

Heavy-duty Cradles

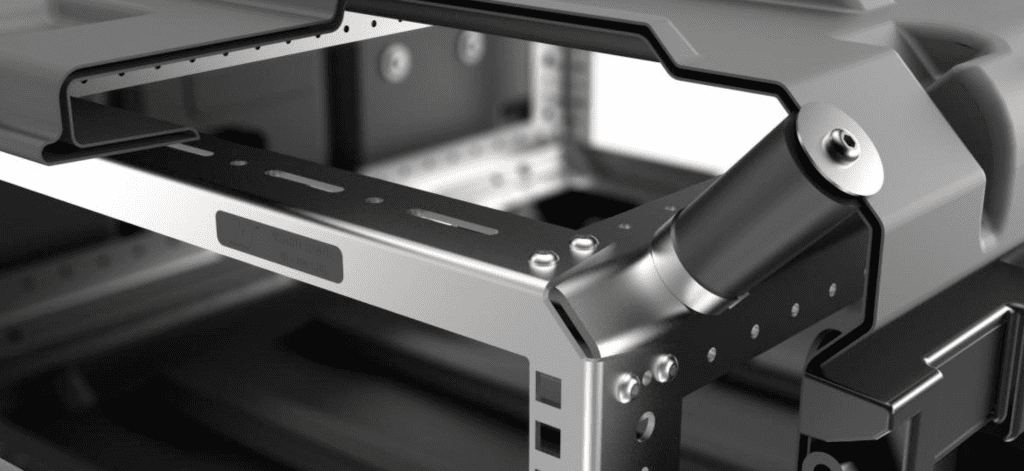

When shock-absorbent foam is not sufficient for your needs, Pelican offers custom cradles or frames designed to hold heavy parts away from the walls of the case. Shock mounts are used to isolate these fixtures from shock and vibration. Shocks can be mounted foam bumpers, or elastomeric (synthetic rubber) shock mounts capable of mitigating impacts up to a force of 15 Gs.

Vibration Control

Small but constant vibration is very destructive to a case. And, if not controlled, it can damage the equipment inside. Fortunately, as you just learned, we can dampen those internal vibrations by securing the equipment to metal decks or cradles isolated from case walls. If, after testing, there is still too much vibration, then we can choose more efficient mounts from our inventory of 20,000 different sizes and densities.

For more information on vibration testing, see “Lab Testing” below.

Lab Testing

To perform a drop test, lab techs install g-force sensors into a box that is the same size and weight of the equipment that will go into that particular case. The sensor box is strapped to the Pelican’s shock-mounted frame, the lid is latched, and the case is dropped at various angles from 18 inches to as much as 24 feet while a computer records the number of g-forces exerted on the box inside. If the number is less than what the customer required, then, once again, Pelican has done its job.