Custom Solutions

Custom Solutions

Custom Foam

Our Advanced Technical Packaging and Design team utilizes the latest software and foam cutting tools to provide precise custom inserts for all of our cases. Additionally, we provide custom services for any project, providing best-in-industry lead times.

Advanced Cases

Advanced Case Solutions are the result of a multi-disciplinary, 4-stage process. Working closely with your team, our engineers customize a protective system according to your product specifications, usage and environmental analysis.

Specialized Services

We offer a number of specialized services, including the fabrication of custom cradles and frames for heavy parts, help with controlling case vibration as well as arranging drop tests, vibration tests and leak tests with independent labs.

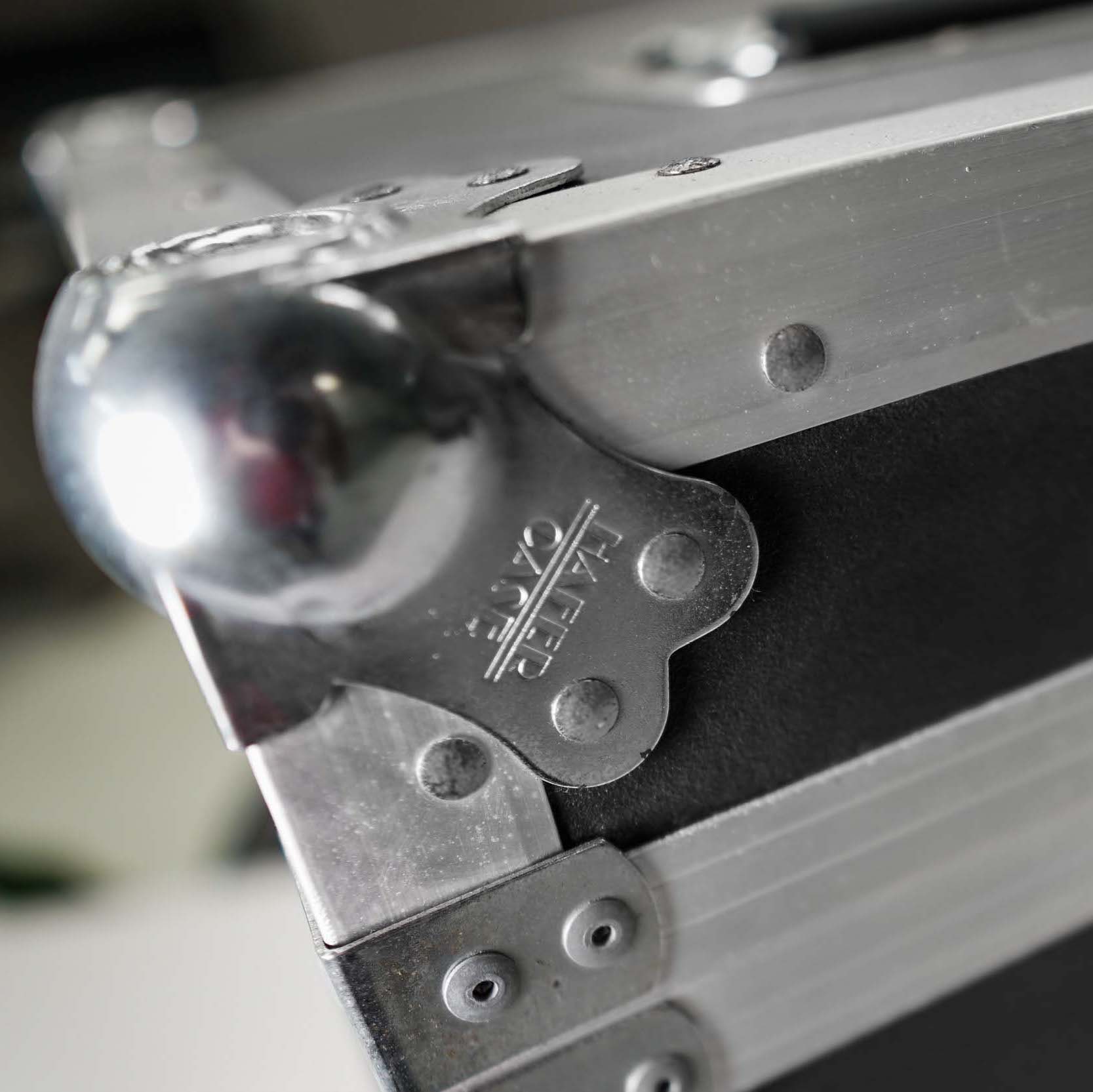

ATA Cases

ATA cases are reusable shipping containers that meet the criteria set by the Airline Transport Association (Specification 300). These cases are required to withstand the rigors of 100 round trips on both surface and air carriers. Our ATA cases are highly customizable and can be altered to meet almost any requirement.

Custom Foam

Our Advanced Technical Packaging and Design team utilizes the latest software and foam cutting tools to provide precise custom inserts for all of our cases. Additionally, we provide custom services for any project, providing best-in-industry lead times.

Advanced Cases

Advanced Case Solutions are the result of a multi-disciplinary, 4-stage process. Working closely with your team, our engineers customize a protective system according to your product specifications, usage and environmental analysis.

Specialized Services

We offer a number of specialized services, including the fabrication of custom cradles and frames for heavy parts, help with controlling case vibration as well as arranging drop tests, vibration tests and leak tests with independent labs.

ATA Cases

ATA cases are reusable shipping containers that meet the criteria set by the Airline Transport Association (Specification 300). These cases are required to withstand the rigors of 100 round trips on both surface and air carriers. Our ATA cases are highly customizable and can be altered to meet almost any requirement.